When it comes to protecting lives and property in commercial buildings, few components are as critical as properly certified door hardware. Electrified mortise locks with UL10C certification stand at the intersection of three essential building systems: access control security, fire safety compliance, and emergency egress. These sophisticated devices aren't simply door locks. They're engineered life-safety components that must perform flawlessly under the most extreme conditions imaginable.

For architects, facility managers, and hardware consultants working on commercial, institutional, or high-occupancy buildings, selecting the right electrified mortise lock for commercial doors requires understanding complex regulatory requirements from the International Building Code (IBC) and National Fire Protection Association (NFPA). This comprehensive guide will walk you through everything you need to know about UL10C certification, how these locks integrate with modern access control systems, and why choosing certified hardware from manufacturers like Camax ensures both compliance and performance.

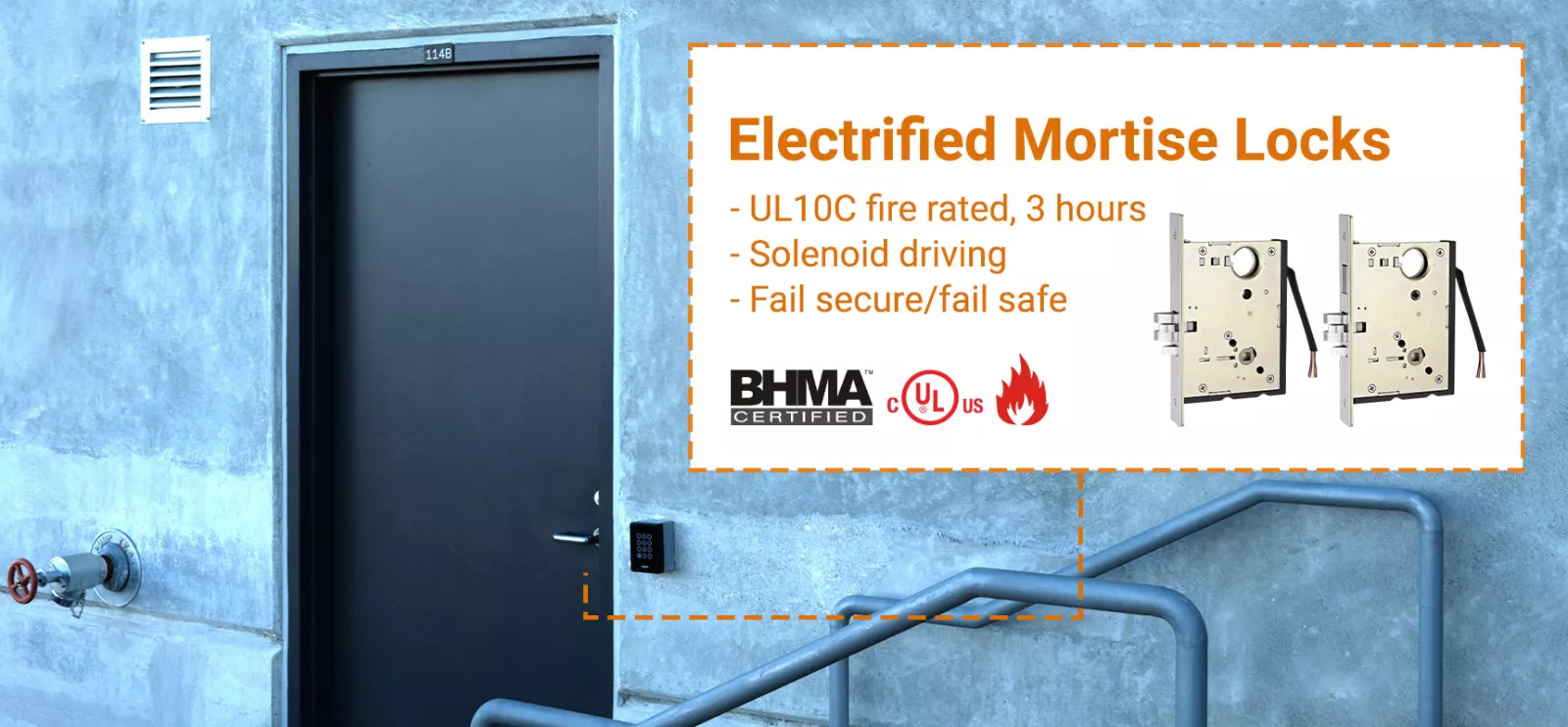

What Is an Electrified Mortise Lock?

An electrified mortise lock represents a significant evolution from traditional mechanical door hardware. While it maintains the robust mortise lock body that's been trusted for decades in commercial applications, it incorporates sophisticated electromechanical components—typically a solenoid or compact motor—directly into the lock chassis. This integration allows the lock to communicate with building access control systems (ACS) in real-time.

The electronic components control the outside lever or handle, enabling or disabling access based on credentials, schedules, or manual override commands. This means a single electric mortise lock can enforce complex security policies: granting entry to authorized personnel during business hours, restricting access to sensitive areas, logging all entry attempts, and providing instant lockdown capability during emergencies.

1. Key Benefits Of Electrified Mortise Door Locks

Compared to purely mechanical locks or surface-mounted electric strikes, electrified mortise locks for access control offer several compelling benefits:

Enhanced Security: The electrified mortise lock with deadbolt configuration provides multiple locking points, making forced entry significantly more difficult than single-point locking systems.

Flexible Access Control: Integration with card readers, keypads, biometric scanners, or mobile credentials enables sophisticated access management without changing the physical hardware.

Audit Capabilities: Many models include monitoring switches that report lock status, door position, and access events to the central security system, creating detailed audit trails.

Fire Code Compliance: When properly certified, these locks maintain fire door integrity while allowing electronic access control—a critical requirement that's difficult to achieve with other hardware configurations.

Egress Safety: The inside lever always remains mechanically unlocked, ensuring occupants can exit freely during emergencies without requiring power or special knowledge.

Tips: Why Choose Electrified Mortise Locks Over Traditional Mortise Locks?

Traditional mechanical locks require physical key management—distributing, tracking, and replacing keys when lost or when personnel changes occur. An industrial electrified lock eliminates these challenges while adding capabilities impossible with mechanical hardware: time-based access, remote unlocking, integration with alarm systems, and instant credential revocation. For modern commercial facilities, the operational benefits typically justify the higher initial investment within the first year of operation. When you combine electrified operation with a UL10C 3-hour fire rating, you get a lock that can both control access and survive severe fire testing.

Why UL10C Certification Is Important for Electrified Mortise Locks?

The UL10C test protocol represents a major advancement over older testing methods. In actual fire scenarios, burning generates hot gases that expand and create positive pressure within the fire compartment. This pressure actively pushes flames, heat, and toxic smoke through any gaps or weaknesses in the door assembly. Earlier test standards like UL10B didn't adequately simulate this pressure differential.

During UL10C testing, the commercial electric locks and door assembly face a brutal three-hour ordeal. Hot gases and flames are actively forced against the door system, with the neutral pressure level positioned no more than 40 inches above the floor within just five minutes of test initiation. This creates maximum stress on the locking hardware, door seals, and frame connections—precisely mimicking the most dangerous real-world conditions.

Tips: What a 3-Hour Rating Really Means?

When a manufacturer like Camax certifies that their electrified mortise lock for commercial doors carries a UL10C 3-hour fire rating, it means the lock has successfully endured the complete test protocol. The hardware must maintain its structural integrity, prevent flame penetration, limit temperature rise on the unexposed surface, and remain functional for egress throughout the entire three-hour burn cycle and subsequent hose stream test.

This certification isn't just about regulatory compliance—it's about real-world performance when lives are at stake. A properly rated fail safe electrified mortise lock ensures that even during a prolonged fire emergency, the door assembly continues protecting escape routes and containing the fire to its compartment of origin. For building owners and occupants, this certification provides genuine peace of mind backed by rigorous third-party testing.

Camax Electrified Mortise Lock Solutions

Camax has engineered its electrified mortise lock product line specifically to meet the demanding requirements of modern commercial construction. Built on ANSI/BHMA Grade 1 platforms, which is the highest durability rating available for commercial door hardware, these locks combine mechanical robustness with sophisticated electronic control capabilities.

Both product lines integrate seamlessly with all major access control platforms and support multiple voltage configurations. Each lock includes factory-adjustable options for fail-safe or fail-secure operation, door position switches, and request-to-exit monitoring, eliminating the need for additional hardware in most installations.

- • Electrified Mortise Locks (Solenoid Driving)

- • Non-handed

- • Certification: A156.13, Grade 1; A156.25; A156.5; UL294; UL10C&CAN-ULC-S104; UL10C fire rated, 3 hours

- • Current: 300mA/150mA

- • Monitoring: Handle, request to exit (REX); Latch bolt (LM); Auxiliary latch (ALM); Key Override (KO); Door position (DP)

- • Fail secure/Fail safe

- • Material: Stainless steel 304/316

- • Standard finishes: Satin finish

- • Electrified Mortise Locks with Deadbolt (Solenoid Driving)

- • Non-handed

- • Certification: A156.13, Grade 1; A156.25; A156.5; UL294; UL10C&CAN-ULC-S104; UL10C fire rated, 3 hours

- • Current: 300mA/150mA

- • Monitoring: Handle, request to exit (REX); Latch bolt (LM); Auxiliary latch (ALM); Key Override (KO); Door position (DP)

- • Fail secure/Fail safe

- • Material: Stainless steel 304/316

- • Standard finishes: Satin finish

Fail Safe and Fail Secure: Which One Fits Your Project?

The terms fail safe and fail secure describe how an electrified mortise lock behaves when electrical power is interrupted. This seemingly simple distinction has deep implications for both life safety and security, making it one of the most critical specifications in hardware selection.

Fail-safe operation means the lock automatically unlocks when power is removed. The electronic components actively hold the outside lever locked during normal operation; when power fails (or is cut during an emergency), the lever immediately releases. This configuration prioritizes egress—ensuring people can always escape even during power outages or when fire alarm systems cut power to door hardware.

Fail-secure operation does the opposite. The lock remains locked when power is lost. The electronics consume power only during unlocking; in their de-energized state, the mechanical components maintain security. This mode is essential for high-security areas where maintaining protection during power failures is paramount, such as server rooms, pharmaceutical storage, or areas containing valuable assets.

| Outside/Inside | SKU | Type | Function Description |

|---|---|---|---|

|

CML850ES | Electrically Secure and Safe, split spindle CML850EL+ES1-TD-EU |

- Outside levers unlocked by 12V or 24V DC electrically, power failure keeps outside lever locked. - Inside levres locked by 12V or 24V DC electrically, power failure keeps inside lever unlocked. - Auxiliary latch deadlocks latchbolt when door is closed. - Latchbolt retracted by key outside any time. |

|

CML850EU | Electrically Unlocked, split spindle | - Outside levers unlocked by 12V or 24V DC. - Latchbolt retracted by key outside or by inside lever. - Switch or power failure keeps outside lever locked. - Auxiliary latch deadlocks latchbolt when door is closed. - Inside lever is always free for immediate egress. - Keys are for the emergency. |

| CML850EL | Electrically Locked, split spindle | - Outside levers continuously by 12V or 24V DC. - Latchbolt retracted by key outside or by inside lever. - Switch or power failure allows outside lever to retract latchbolt. - Auxiliary latch deadlocks latchbolt when door is closed. - Inside lever is always free for immediate egress. - Keys are for the emergency. |

|

|

CML852EU | Electrically Unlocked Both Sides, solid spindle | - Outside and inside levers unlocked electrically. - Latchbolt retracted by key either side. - Switch or power failure keeps inside and outside levers locked. - Auxiliary latch deadlocks latchbolt when door is closed. - Keys are for the emergency. |

| CML852EL | Electrically Locked Both Sides, solid spindle | - Outside and inside levers continually locked electrically. - Latchbolt retracted by key either side. - Switch or power failure allows inside and outside levers to retract latchbolt. - Auxiliary latch deadlocks latchbolt when door is closed. - Keys are for the emergency. |

|

|

CML855EU | Electrically Unlocked (with deadbolt), split spindle | - Function same as CML850EU, deadbolt as additional point of locking. - Deadbolt thrown and retracted by key outside and thumbturn inside. - Also could be retracted by both side levers. - Inside lever is always free for immediate egress. - Auxiliary latch deadlocks latchbolt when door is closed. - Keys are for the emergency. |

| CML855EL | Electrically Locked (with deadbolt), split spindle | - Function same as CML850EL, deadbolt as additional point of locking. - Deadbolt thrown and retracted by key outside and thumbturn inside. - Also could be retracted by both side levers. - Inside lever is always free for immediate egress. - Auxiliary latch deadlocks latchbolt when door is closed. - Keys are for the emergency. |

Custom Manufacturing and OEM/ODM Solutions From Camax

Architectural hardware increasingly demands customization—whether for aesthetic coordination with interior design, functional adaptation to unique door configurations, or branding requirements for large installations. Camax has invested heavily in OEM/ODM capabilities precisely to address these needs without compromising the certification and quality that makes their hardware reliable.

1. Tailored Design Solutions

Camax's engineering team can modify virtually every aspect of their electrified mortise lock products while preserving core mechanical and electronic functionality. Customization options include aesthetic modifications, functional adaptations, master key systems and special compliance.

2. Maintaining Certification Through Customization

One of the most significant challenges in custom hardware is maintaining essential certifications. Camax explicitly preserves ANSI/BHMA Grade 1, UL10C fire rating, and CE marking throughout the customization process. This is possible because customizations are carefully engineered to avoid compromising tested components or assemblies. Color finishes, trim variations, and electronic modifications are implemented without affecting the core lock body that underwent certification testing.

3. Scale and Technical Support

With nearly two decades of experience since the company's founding in 2006, Camax possesses the production capacity to support projects of virtually any scale. Camax's R&D team manufactures to specification and provides technical consulting on product selection, access control integration strategies, and installation methodologies.

This consultative approach proves especially valuable for wholesalers and large contractors managing multiple simultaneous projects. Rather than simply fulfilling purchase orders, Camax functions as a technical partner throughout the specification and procurement process, helping ensure the selected hardware truly matches each project's functional and regulatory requirements.

Contact Camax to Secure Your Project with Certified Solutions

Specifying electrified mortise locks for commercial applications requires balancing security functionality, fire safety compliance, egress requirements, and access control system integration. UL10C certification isn't simply a checkbox on a specification sheet. It represents rigorous third-party validation that the hardware will perform as needed during the most critical moments.

Camax's commitment to manufacturing Grade 1, UL10C-certified commercial electric locks while offering extensive customization capabilities provides architects and facility managers with a rare combination: door hardware that meets the highest standards while adapting to project-specific requirements. Whether you're specifying standard catalog products or require custom solutions, the underlying quality and certification remain consistent.

Ready to specify certified electrified mortise locks for your next project? Contact Camax today to discuss your specific requirements, explore OEM/ODM possibilities, or receive technical consultation on hardware selection and system integration.

Need help? Contact Camax for a quote!

Discover Camax's door & window hardware with ANSI/BHMA/UL/CE certification today!